Solder or Crimp Wires

Article by Mark Trotta

When two electrical wires need joining, they can be soldered together or crimped together. So which way is better? To me, circumstances dictate which method to proceed with.

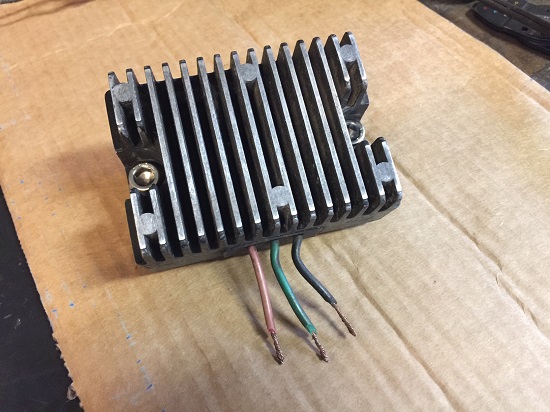

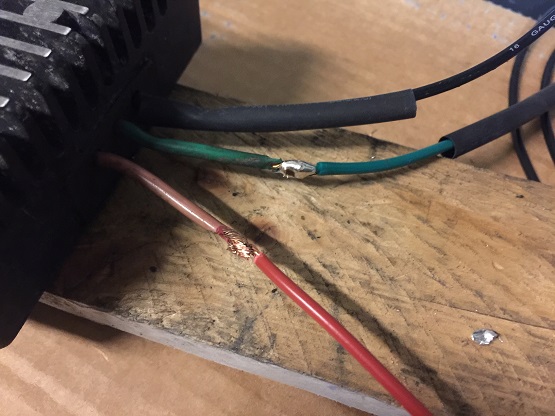

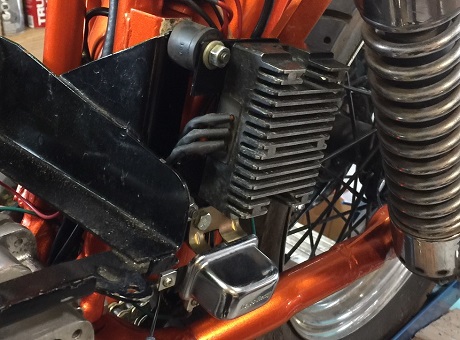

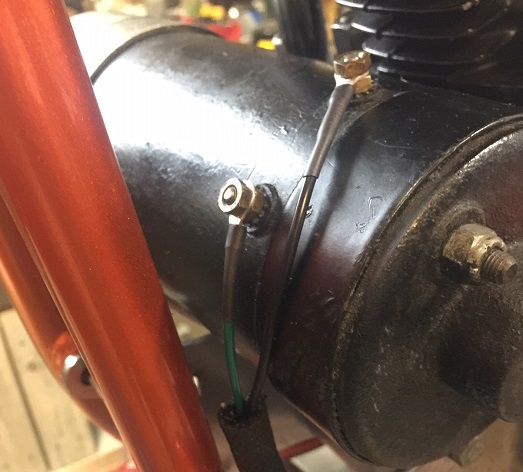

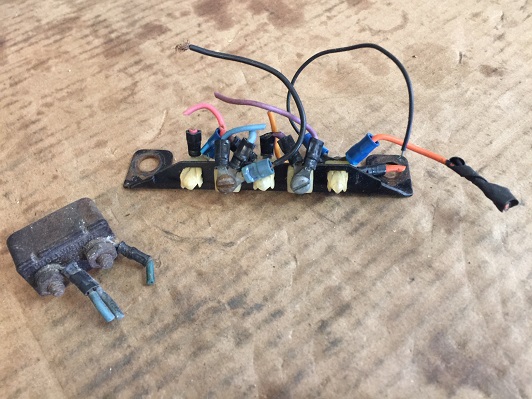

So, why solder wires and other times crimp wires? For purposes of this discussion, I'm using a voltage regulator I've installed on a 1974 Sportster as an example. It's a later style "solid state" electronic unit that's replacing an original mechanical unit. As you can see, there wasn't much left of the wires.

Joining Wires By Soldering

Soldering was chosen over butt connectors for several reasons. First off, there wasn't much left of the old wires to connect the new wires to. Secondly, there were three wires right next to each other--butt connectors would be too fat, especially when routing into a tight spot or going into a wiring harness.

Lastly, soldered wires look better than when using butt connectors.

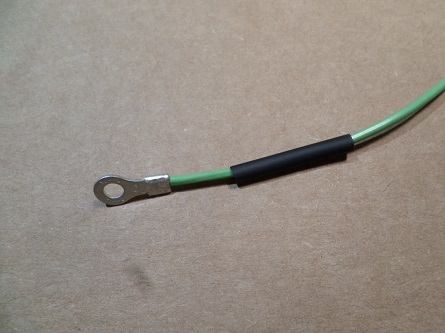

Crimping Wire Terminals

Crimping wires correctly requires an inexpensive tool.

When I install crimp connectors, I take off the plastic sleeve it comes with. IMHO, an inch or so of shrink tubing looks better.

After crimping the terminal, check tightness by pulling on it with your fingers.

Heat the shrink tubing with a lighter. The wire terminal connections are now sealed and protected.

Connecting Wires With Butt Connectors

There is little skill required to connect two wires with a butt connector. Because of that, or in spite of it, they are often seen as an amateurish attempt to repair wiring.

Although they have a reputation for being misused and over-used, butt connectors make a fast and easy repair when installed correctly.

Wiring Harness Replacement

On the same bike as the voltage regulator swap, I replaced the 45 year-old wiring harness with an aftermarket harness. It was advertised as an exact factory replica, and I was a little surprised when it arrived and it had crimp-on terminals. But after looking at what was left of the old harness, I found that this was correct- that's exactly what the factory did back in the 1970s.

After a little research, I learned that the automotive and motorcycle industry started crimping terminals as early as the 1950's. This was not done because it's better than soldering wires, it was done because it's cheaper and faster.

How To Solder Wires

- Strip both ends of wire with wire strippers

- Cut a piece of heat-shrink tubing

- Slip it over one end of the broken wire, sliding it up and away from the repair area

- Solder the wires back together using resin-core solder

- After the repair has cooled, slip the shrink tubing over the repair

- Heat the tubing and allow it to shrink over the soldered wire

Do I Need To Use Flux When I Solder?

The key to getting a good solder joint is a chemical cleaning agent known as flux. Most common solder wire is rosin-core, which has one or more cores of flux inside of it. There's no harm in adding additional flux, but probably not needed if you're starting with a quality brand solder wire.

The actual soldering process isn't long, but the setting up process is long. If you don't have a soldering gun, you'll need to get one. Most soldering pencils don’t create enough heat, so a soldering gun is mandatory.

I've had this same Weller soldering gun for 30+ years, and aside from changing the tips several times, it's performed flawlessly. The original design was so good, that if you bought a brand new one today, it'll look just like this one!

Shop: Weller Soldering Gun Kit

The Weller D550PK soldering gun kit includes 3 tips, solder, and storage case.

Do not use acid core plumbing solder for electrical work, use a good quality rosin core solder.

Shop: Tin-Lead Rosin Core Solder Wire

Solderless Wire Connectors

Wire crimp connectors do not require soldering and are an easy method for repairing broken wires.

Heat Shrink Connectors

An alternative to removing the hard plastic sheath of the terminal and adding shrink tubing is to buy heat-shrink terminals.

After crimping the terminals on with crimping pliers, apply heat with a lighter while rotating the connector. The heat shrink tubing reduces in size and adheres to the wire.

************************

Conclusion

Although soldering and shrink-tubing wires is a great way to repair electrical wires, there is always a time factor in doing any motorcycle repair. When done correctly, crimping is not any better or worse than soldering -- it's just cheaper and faster.

If time was never a factor, I'd probably solder wires together most of the time. But when I'm custom fabricating single wires or harnesses, I'll most always use crimp-on terminal ends. Either method works.

************************

Related Articles:

Basic Motorcycle Wiring

Motorcycle Maintenance

Wiring A Motorcycle From Scratch