Pinion Gear Removal Norton Commando

Article by Mark Trotta

The last thing to do before separating the cases on the '74 Commando engine was remove the pinion gear.

Like many other British Twins (Triumph, BSA, and others), the Norton pinion gear is a press fit onto the crankshaft. A specialty tool is usually needed, but if the gear is not that tight, you may be able to pry it off with a pair of small pry bars or flat-blade screwdrivers.

If the old gear happens to slip off the shaft without any effort, you have a worn-out gear. It's best to replace a loose gear, otherwise you'll have excessive noise.

And if it's on there tight, you're buying the special extractor tool.

The only tool currently available is actually for BSA and Triumph Twins, but may need modification to work on Norton Twins.

The tool cost about $65. I purchased mine from The Bonneville Shop in Montana.

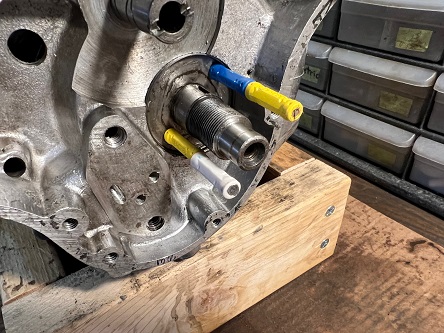

Pictured above, aftermarket crankshaft pinion extractor puller. The Norton service part number is 61-6019.

*******************

Pinion Removal Tool Issues

If the gear is not that tight, the puller may work as is. But if it's stuck tight, the jaws will slip off, in which case the tool needs to be modified to work.

This is because the jaws on the puller are curved, and don't properly fit under the Norton gear.

The Fix

After securing it in soft jaw pads in a workbench vise, the outer edges of each jaw were ground down slightly with an electric grinder.

If you're using a hand-held electric grinder, grind for no more than five or ten seconds on each jaw, then stop and check. You don't need or want to take too much off.

The jaws don't need to be perfectly flat straight across. The ends just need to be ground down slightly, like in the pictures.

The entire grinding process took less than three minutes.

*******************

Extractor Tool In Use

To use, back off the puller sleeve until the three legs are extended enough to reach behind the gear, then hand tighten the knurled body. Next, thread the center bolt snug to the shaft.

TIP: before using extractor tool, spray some WD40 or similar penetrant onto the gear and let soak.

Slowly turn the outer bolt head with a wrench or socket. If all goes well, the pinion will begin to back off from the crankshaft.

Heating up the area beforehand will also help.

With the jaw's outer ends ground flat, the puller got a good bite on this tight gear!

*******************

Back Plate and Sealing Washer

After gear is off, the crankshaft pinion back plate (the triangle-shaped washer) can be pulled out.

The washer tends to stick because of the oily surface. A few magnetic sticks from a children's board game helped remove it.

Once that was out of the way, the sealing washer (oil sealing disc) can also be removed with magnets.

After the woodruff key was removed, the cases were separated.

A couple of taps with a mallet on a clam shucking tool gave just enough room for a gasket scraper.

*******************

Engine Work Box

Here's a simple wooden engine stand for Norton Twins.

Materials needed are four pieces of 2x4 lumber and eight screws.

Total work box cost was about five dollars.

For more DIY motorcycle tools click here

*******************

Related Articles:

Norton Commando Build - Main Page

Remove Cylinder Head

Timing Cover Removal and Installation

Sludge Trap Cleaning and Crankshaft Reassembly

Bottom End Assembly

Timing Chain Installation