Motorcycle Valve Job

Text and Pictures by Vintage Vinny

Proper valve seating is crucial to a strong-running engine.

Engine valves have three functions:

- Supply air/fuel mixture to the combustion chamber.

- Remove unwanted fumes from the combustion chamber.

- Remove unwanted heat through the seats and guides.

To do all these things effectively, valves must properly seal every time they open and close.

Disassembly And Inspection

With the head(s) removed from the motor, disassembly is straightforward. Removing the valves releases the valve springs and retainers.

****************************

Related Article: Clean Carbon Off Cylinder Heads

****************************

A valve spring compressor is necessary to remove valves. Once removed, the valves, guides, springs, and valve seats can be checked for wear and/or damage.

Check/Replace Valves

Used valves should be checked for wear, pitting, burning, and cracks. Any signs of these and you'll want to replace the valve. Look for pitting on the face, margin, and stem.

Carbon build-up is common on engine valves, but be careful when removing, you don't want to scratch the face of the valve.

Since exhaust valves run much hotter than intakes, many engine builders will replace exhaust valves automatically. This is cheap insurance against possible failure.

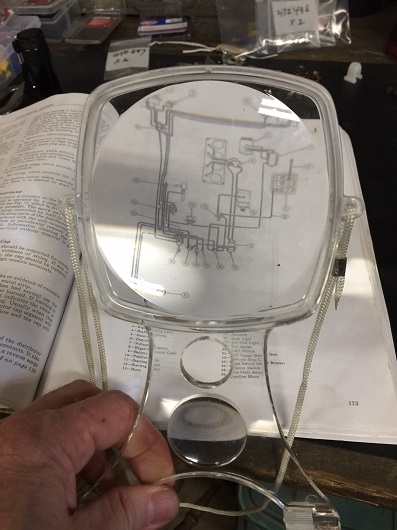

A magnifying lens with a large viewing area will help you check for small hairline cracks.

Check/Replace Valve Springs

Valve height affects valve train geometry and guide wear. Old valve springs can be tested and/or measured to make sure they are capable of maintaining proper pressure.

Most factory service manuals list a minimum valve spring height for re-use. A good rule of thumb is, replace old spring if there's any more than an 1/8" of difference.

Valve Spring Shims

In a non-performance motor, slightly worn valve springs may be shimmed to restore proper valve height. This is sometimes necessary when valves and seats are machined.

Check/Replace Valve Seats

If the head in question has had several valve jobs in the past, the valve seat may be "sunk" into the head. This means the top of the valve will stick out taller than the others, which alters valve train geometry.

For either of these scenarios, seat replacement is the only option.

If the valve seats are only worn slightly, they can often be be cut or ground to restore the sealing surface. This is done only after the valve guides are checked and/or replaced.

****************************

Check/Replace Valve Guides

Old valve guides should be to be checked for wear.

Read: How To Measure Valve Guide Wear

If they are worn and out of spec, they should be replaced. A cheaper option is to renew them by knurling.

Read: How To Install Valve Guides/Knurling vs Replacing

****************************

Can't I Just Lap My Valves?

Many weekend mechanics, faced with old and worn valve seats, decide to just lap the valves and reassemble the cylinder. Obviously, this is done because of time and money constraints.

Remember that valves help transfer heat out of the engine. If you decide to just lap the valves and the seat is too narrow, excess heat builds up inside the head. We all know the dangers of running hot, especially an air-cooled engine.

If the seat is too wide, you're robbing the engine of power.

At best, valve lapping will clean up very light wear on a low-mileage head. Anything more than that, lapping is not effective.

Proper Valve Seat Width

Many factory shop manuals specify an optimum seat width of .050". Some engine builders will cut them a little thinner than factory settings. This gives slightly better performance but slightly shorter life.

Reassembly

Old valves, springs, collars, and keepers should be checked for wear before reinstalling. If anything looks questionable, replace it.

Note: Some cylinder heads are designed to have valve stem seals, others aren't.

The use of three-angle seats in cylinder heads has been an industry standard for decades. This is done by cutting relief angles above and below a 45 degree center contact surface.

****************************

Aluminum Cylinder Heads

Aluminum is lighter and easier to repair than cast-iron, but it's also more fragile. Before rebuilding aluminum cylinder heads, check for cracks and warpage.

****************************

Related Articles: