Motorcycle Repair Tools And Equipment

Most classic bike owners like to do their own repair work. If you're new to the hobby, learning to do maintenance and repairs is worth your time.

Tools and equipment for motorcycle repair are often the same as those used for automotive repair. Besides basic hand tools that you probably already have, here's some that I've found helpful for all phases of motorcycle repair and restoration.

***************************

Tap And Die Set

If you're restoring an old motorcycle that's been neglected, I would rate a tap and die set as a necessity.

With proper technique and lubricant, taps and dies will cut mild carbon and alloy steel, cast iron, aluminum, brass, and bronze.

***************************

Related Article: Motorcycle Engine Tools

***************************

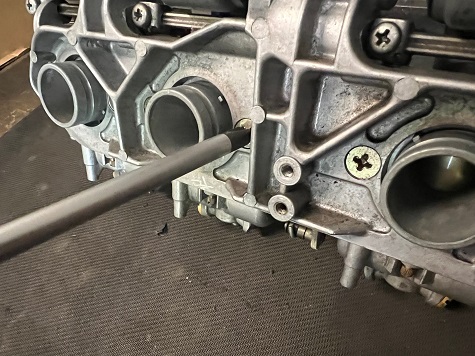

Specialty Tools

Every brand of motorcycle will require a unique specialty tool or two.

The tool in the above picture is for installing piston lock-rings in early Harley-Davidson 45 flatheads. It lightly stretches the lock ring just enough to fit into the groove. The factory part number for this tool is 12052-32, and it's primary use is for 1932-1956 Harley-Davidson 45 models, but works for some other models as well.

***************************

Whitworth Tools

British motorcycles that have Whitworth fasteners include Ariel, BSA, Matchless, Norton, Triumph, and Vincent.

Read: What Are Whitworth Tools?

***************************

Related Article: Best Hand Tools

***************************

Cannon Plug Pliers

Cannon plug pliers come in handy when removing or installing round things without damaging or scratching them.

***************************

Torque Wrench (Foot-Pounds)

For those who haven't used a 'click-style' torque wrench before, you set the desired value on the handle scale, then begin tightening the fastener. When the preset torque value is reached, the wrench will emit a "click" that will be heard and felt.

Shop: 1/2" Torque Wrench (10-150 ft/lbs)

A 1/2" drive torque wrench will generally cover your needs up to 150 foot/pounds. It is recommended to torque bolts in increments; example, first pass 20 ft/lbs, then 40 ft/lbs, then 60 ft/lbs, etc. until desired torque value is reached.

Stay away from beam-style torque wrenches. Most are inaccurate, and all of them hard to read while you're using it.

Torque Wrench (Inch-Pounds)

On the lower end of the scale are 1/4" drive torque wrenches. These are nice to have for smaller bolts that require less torque.

Shop: 1/4" Torque Wrench (20-200 in/lbs)

***************************

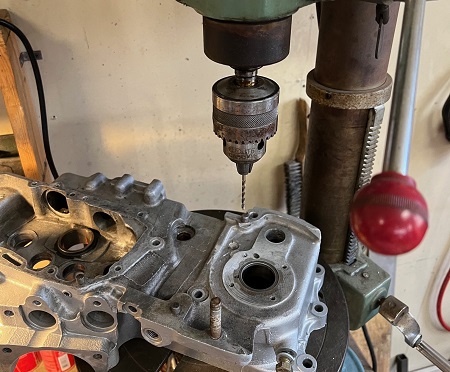

Drill Press

A drill press will surprise you with how many things it's capable of doing. Add a few attachments, and it's even more useful.

Read: 7 Drill Press Uses For Motorcycle Repair

***************************

DIY Motorcycle Tools

Read: DIY Motorcycle Tools

***************************

Wheels and Tires

For enthusiasts who handle all their own maintenance, a wheel balancer stand is a must-have.

A set of motorcycle tire spoons are required to remove and install tires.

***************************

Getting tired of crouching down on your hands and knees while working on your classic bike? Having a motorcycle lift stand saves you time and space, and makes working on your old scoot more enjoyable.

Read: Motorcycle Lift Stand Review

If a lift stand is not in the budget, consider making a work stand.

Read: DIY Motorcycle Work Stand

***************************

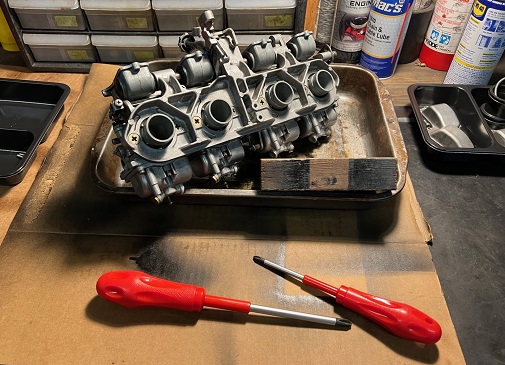

What is a JIS Screwdriver?

Does your Phillips screwdriver feel like it doesn't quite fit?

That's because it's probably not a Phillips screw, it's a JIS screw.

JIS stands for "Japanese industrial standard", and JIS screwdrivers are designed to be used on Japanese products and vehicles.

Read: What Is A JIS Screwdriver?

***************************

Ironhead Sportster Tools

Read: Ironhead Specialty Tools

***************************

Camera

Taking pictures before and after is extremely helpful during re-assembly. A digital camera is nice to have, but a smart-phone works just as well.

TIP: Put a with a screen protector on your phone!

***************************