Ironhead Stroker Build

Article by Mark Trotta

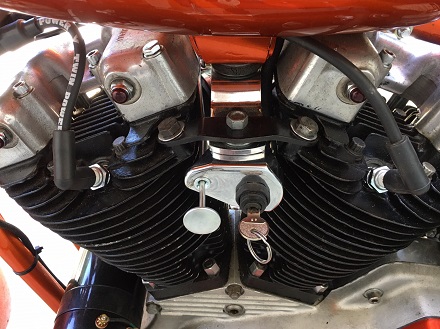

A previous owner wanted to make this 1974 Harley Sportster a little faster, so a stroker kit was installed, but the motor was never completed. The bike sat unfinished for several years, eventually being sold to it's present owner, who then contacted us to "get it running."

Why Stroke?

One of the ways to get more power out of an engine is to increase displacement. This can be done by either enlarging the bore diameter, or increasing the piston stroke length.

You can't bore Ironhead cylinders very much. On a 1000cc engine with a .060" over-bore, displacement increases to 1025cc. But by adding a 4-5/8" stroker kit, displacement increases to 1200cc.

*********************

Here's a few issues you will encounter when you stroke an Ironhead Sportster:

Engine Cases May Need Notching. Depending on the length of the stroke, the inside tops of the engine cases may have to be notched for clearance.

After removing the rocker boxes and cylinder heads, the up and down movement of the connecting rods confirmed that this engine had a 4-5/8" kit installed. Unbolting and lifting up the cylinders revealed the cases had been notched for clearance.

Cylinder Oil Return Holes

Near the bottom of Sportster cylinders, there are oil drain holes. If you use stock cylinder jugs with a stroke length of 4-7/16" or longer (this includes 4-5/8" kits), the oil rings will touch and/or cross the oil holes using stock jugs. This would allow oil to return above the oil ring, which causes excessive engine smoke and oil consumption.

To prevent unwanted smoking and oil consumption, the oil holes need to be relocated. This is when using stock cylinder jugs with a stroke length of 4-7/16" or longer.

Read: Sportster Cylinder Oil Hole Relocation

*********************

Ironhead Stroker Jugs

The alternative to relocating the oil drain holes on longer strokes is to find and install taller "stroker" jugs. Back in the day, larger flywheels, rods, and cylinders were far more common. Today, these parts are hard to find.

We were unable to determine where these cylinders came from, but they are taller than stock and had oil holes in the correct places. The extra height of the cylinders led to several other fitment issues!

Taller Cylinders Raise The Rocker Boxes. So now, the original push rods and oil lines may be too short. Sometimes you can adjust the push rods all the way up on their platforms, but you just might be buying longer push rods and installing custom oil lines.

Frame to Head Clearance. There's not much room above the rear rocker box to begin with, and with taller jugs, there was less than 1/2" of clearance. So if you go this route, consider what frame your motor sits in. If it's an aftermarket hardtail, there may not be enough clearance.

The factory top motor mount was now too thick, so a new mount had to be fabricated.

The factory coil bracket was now too long, so it needed to be trimmed.

An inch was cut off each side, then bolt holes were re-drilled.

Another solution would have been to relocate the coil to another place on the bike.

*********************

Flywheel Timing Marks

When you install larger flywheels, you cannot rely on the flywheel timing marks to be what you think they are. So, finding top dead center is a must.

There are several methods to determine TDC.

In our case, the cylinder heads were off, so with the front piston all the way up, a single dot (".") appeared in the window. This would be our TDC.

This vertical line ("I") is a timing reference mark. The breather valve was set to this mark.

This is what S&S Cycle says about timing a stroker motor:

" ....due to the large number of factors involved, optimum timing is impossible to accurately predict and must be determined for each engine by experimentation."

*********************

Other Performance Mods

Besides 20% more displacement that the stroker kit gave this engine, other performance upgrades included a set of Veglia high-lift cams.

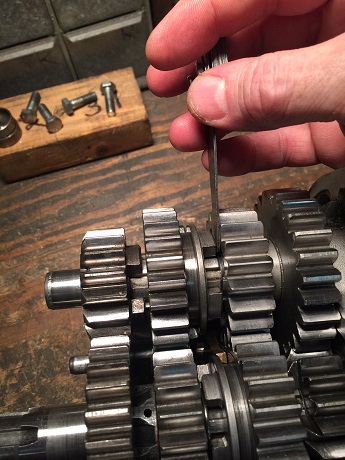

The cylinder heads were rebuilt to stock specs, with new valves, guides and springs. To handle the extra torque, the transmission was gone over.

Read: Sportster 4-Speed Transmission

The stock Bendix carburetor was initially retained for start-up and engine break-in. It will likely be replaced with an S&S Super E.

Read: Best Carburetor For Ironhead Sportster

*********************

Exhaust Pipe Fitment

Because of the taller jugs, the front pipe now angled out slightly.

Allen-type exhaust clamps were fitted, which allowed easy access with a hex wrench.

*********************

Engine Start-Up

Upon start-up, the motor was brought up to a fast idle to help the rings seat, run for just three minutes, then shut off and allowed to cool down. It was then run for five minutes, shut off, and allowed to cooled down. This 'cycling' procedure helps avoid unwanted heat.

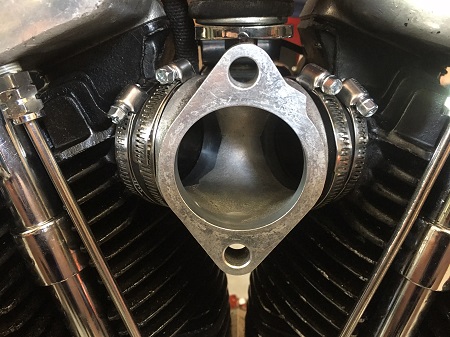

Intake Manifold Fitment

With the taller cylinders, the two manifold inlets now sat further apart, decreasing the area that the two rubber intake gaskets over the carb flanges can cover. This caused the carb to shake quite a bit while running. This led to rough running, and then, while idling, the carburetor and manifold vibrated off!

To remedy this problem, two additional hose clamps and a carburetor bracket were added.

NOTE: Although a Sportster carb mounting bracket can be bought, it wouldn't work on this motor due to the taller height. We were able to fabricate one fairly easily from a metal shelf bracket.

A carburetor support bracket is a good idea on any Sportster motor.

*********************

Aftermarket Stroker Kits

As of 2025, S&S Cycle still offers a 4-5/8" stroker kit for 1971 through 1985 Sportsters. Kit #32-3055 includes flywheels and rod assembly, already assembled and balanced. Pistons are not included and can be purchased separately.

With the standard Ironhead cylinder bore of 3-3/16", the S&S kit increases engine displacement from 1000cc to 1200cc. So, a 61 cubic-inch motor becomes a 74 cubic-inch motor.

NOTE: Numerous companies offer the S&S kit, they're all the same kit.

Although no longer commercially available, stroker kits for Ironheads have also been offered in other sizes, including 4-1/2" and 4-7/16".

*********************

Conclusion

Ironhead Sportsters are known to be finicky machines, and changing major components doesn't help that. But just like every other engine, they'll be as reliable as you build them.

*********************

Related Articles:

Ironhead Engine Build

Remove and Install Clutch (1971-1984)

Engine Assembly (1977-1985)

Remove/Install Cam Bearings

Ironhead Sportster Cylinders