Ironhead Sportster Cylinder Head Removal

Text and Pictures by Mark Trotta

Whether you need to remove one or both cylinder heads from your Ironhead Sportster, they'll be quite a bit of disassembly involved. This article covers each step of the removal procedure.

In my now-obsolete factory manual, labor rate is 2.0 hours for the front head, 2.2 hours for the rear head, and 2.7 hours for both. And being 40+ years old, they'll likely be other issues along the way.

Cylinder head removal is the same process for all year Ironheads 1957 through 1985.

********************

Ironhead TDC

Before dismantling, set engine to Top Dead Center. This will make it a little easier when reassembling. To find TDC, remove timing plug on the left side of the engine between the two cylinder jugs. Turn engine over until the TDC mark comes up.

There are several marks on the flywheel (one dot, two dots, vertical line). On most Ironheads (like this 1981 XLH), the single dot (".") indicates TDC. It's best to check the factory service manual.

The vertical line ("I") pictured below is not Top Dead Center.

This is a timing reference mark. The breather valve is set to this mark.

TIP: Rotating the engine is much easier with the spark plugs removed.

If your bike has a kick-start, you can turn the motor over with the kick pedal.

For non-kick start bikes, raise the rear wheel off the ground an inch or two, then with the bike in gear, turn the rear tire by hand. This will slowly turn the flywheels.

********************

To start the disassembly process, remove carburetor, intake manifold, and exhaust pipes.

Push Rod Cover Removal

The easiest way to remove the push rod tube covers is with the proper tool. This is what the Motion-Pro 08-0255 does so well.

The flat portion of tool fits under the cylinder head, and the cupped end fits over the bell in the tube.

When you squeeze the two handles, the spring compresses, and allows easy access to the spring cap retainer.

When adjusting Ironhead valves, this tool is a real time-saver.

Once the retainers are off, upper covers can slide down into lower covers.

Four pieces of mechanic's wire bent to shape will hold up the lower tubes up and out of the way while loosening the tappet screw locknuts.

Loosen tappet screw locknuts and thread adjusting screw all the way down into the tappet body. Push rods should now be loose enough to come out.

If your tappet screws or locknuts are damaged you can buy replacements here.

To help re-assembly, label push rods in the order in which they came out (RE, RI, FI, and FE).

Loosen and remove any wires that may be in the way.

********************

Ignition Coil, Spark Plugs, Key Switch

Moving over to the left side of the bike, remove ignition coil and spark plug wires. You can leave the spark plugs in, but loosen them so that they'll come out easier when on the work bench.

Two bolts (and a few wires) hold the horn and ignition key bracket.

Late Ironheads (1977 and up) have upper engine brackets on top of each head, which bolt to the frame.

********************

Rear Cylinder Head Is Removed Last

One of the quirks of an Ironhead motor is that the rear cylinder head and rocker box must be removed together. If you try to remove just the rear rocker box, you may damage the gasket surface.

This shortcoming was addressed and corrected on 1986-up Evo Sportsters.

Remove Front Cylinder Head First

There is plenty of clearance above the front cylinder head. The front rocker box can be removed by itself, then the head can come off.

Once the front head is off, there's more space to slide out the rear head and rocker box.

Head Bolts

Each head bolt (four per head) should be at 65 ft/lbs, and it's a tight clearance to get to all of them. Having an assortment of deep and shallow sockets and several sizes of ratchet extensions comes in handy.

Early vs Late Head Bolts

Early Ironheads (1957-1972) have 6-point 9/16" diameter head bolts.

Later Ironheads (1973-1985) have 12-point 7/16" diameter head bolts.

******************

Stuck Head

Cylinder jugs are often used as a platform for prying off a stuck head. This is never a good idea, as fins can be easily broken.

Check that all the bolts are out, and then try tapping lightly with a rawhide or plastic hammer.

Damaged Heads

Before attempting repair on a cylinder head, consider the following; does it have worn valve guides AND bad valve seats AND broken fins? If so, it'll probably be more cost-effective to find a replacement head.

Before and after cracked fin repair, Ironhead Sportster.

Read: Cracked Cooling Fin Repair

Read: How To Measure Valve Guide Wear

******************

Cleaning

After the heads are off, there are many methods to clean off carbon, including soda blasting, media blasting, vapor blasting, walnut shell blasting, etc. The least expensive way to clean off carbon build-up is with degreaser and a wire brush (brass brush for aluminum). This method will take longer, but it's cheap and gets the same results as the others.

******************

Rocker Box Rebuild

Read: Ironhead Rocker Box Assembly

Read: How To Polish Aluminum Motorcycle Parts

********************

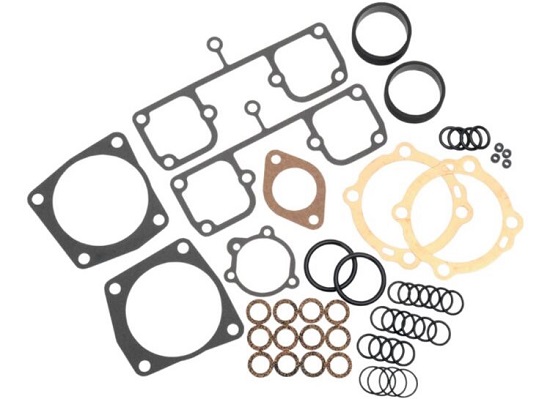

Top End Gasket Kit

James Gaskets are simply the best gaskets available for your old Harley. Their top-end gasket kit replaces H-D 17030-72 and includes everything you need to re-seal your top end.

James Gaskets are made in the U.S.A.

******************