Ironhead Cylinder Head Cleaning and Inspection

Disassembly and inspection will go easier and a whole lot more enjoyable after cylinder heads are clean.

There are many methods to clean off carbon, including soda blasting, media blasting, vapor blasting, walnut shell blasting, etc. The least expensive way to clean off carbon build-up is with degreaser and a brass brush. This method will take longer, but it's cheap and gets the same results.

Remove any carbon build-up on the port-side of valve guides. You don't want any debris getting into the guide hole.

******************

Disassembly

A Valve Spring Compressor is needed to remove valves and springs.

Read: Ironhead Cylinder Head Removal

After compressing, the two small keepers (valve spring retainers) are removed, allowing the springs, collars, and valves to come out.

If collars are damaged or missing you can buy replacements here.

NOTE: Valve spring collars For 1983-1985 Sportsters are different than earlier years.

******************

Removing Rust and Corrosion

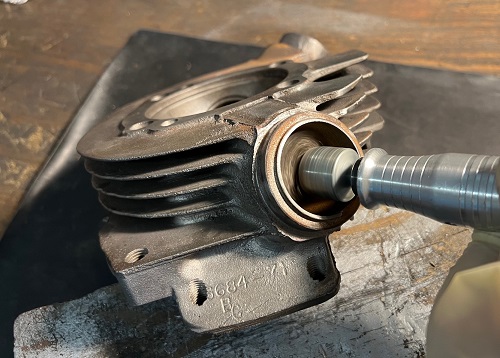

After removing the springs, collars, and valves, removing rust and corrosion from hard to get to places can be done by hand with Emory cloth, but an electric rotary grinder get it done in a fraction of the time.

Removing rust from intake port with small wire wheel

Read: Foredom Rotary Shaft Tool Review

******************

Cylinder Head Inspection

Visually go over the entire head. Any broken fins or stripped threads?

Check valves for pitting and corrosion.

******************

Valve Springs

On inner springs up to early 1983, free length should be 1-23/64"

On inner springs early 1983 and later, free length should be 1-9/16"

On outer springs up to early 1983, free length should be 1-1/2"

On outer springs early 1983 and later, free length should be 1-9/16"

Valve springs should be replaced if worn or damaged. Replacements springs are available here.

******************

Inspect Valve Seats

Carefully inspect the valve seats. Are any of them worn, burnt, or pitted?

Do you have any history of the bike? Chances are the heads have been off before. With each valve job performed, valves will "sink" a little deeper into the head, which alters valvetrain geometry.

Read: Motorcycle Valve Job

The factory spec for valve stem protrusion is 1.420 inches.

******************

Inspect Valve Guides

Valve stem clearance for factory cast-iron guides is:

Intake - .0015" to .0035"

Exhaust - .0035" to .0045"

There are several ways to check valve guides for excessive play.

Read: How To Measure Valve Guide Wear

NOTE: There are instances where, even with proper measuring tools, precise measurement may not be attainable. In that case, it's best to replace anything questionable.

******************

On a 40+ year-old motorcycle, cylinder head work may include repairing cracked cooling fins and repairing stripped threads.

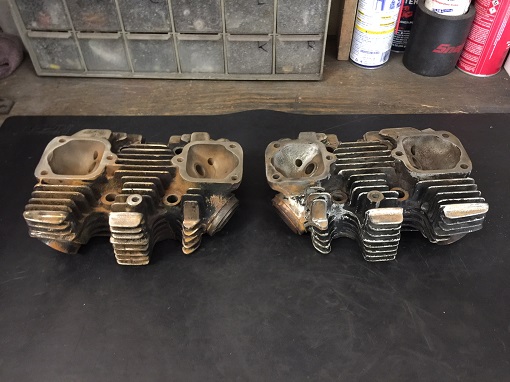

Before repairing broken fins on a cylinder head, check valve seats and guides. If they need replacing AND you have broken fins, it'll be more cost-effective to find another head.

Before and after cracked fin repair

Read: Cracked Cooling Fin Repair

******************