Harley 45 Bottom End Assembly

Text and Pictures by Mark Trotta

Next up on the Harley 45 engine build was installing the flywheel assembly, checking crankshaft end play, and finally, bolting up the engine cases.

Right-Side Roller Bearings

With the right-side case laying flat, the right-side bearing washer (the one with the tab) is installed into the right case, then the right-side roller bearings (the two-piece cage) are dropped in.

Next, the right-side case was propped up and flywheel assembly went in.

Left-Side Roller Bearings

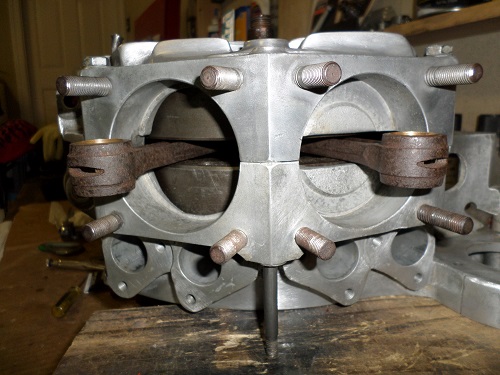

The left-side roller bearings (the two one-piece cages) are now installed, followed by the bearing washer on the left-side (threaded) sprocket. At this point, the left case should fit easily on top of the right case.

======================

Harley 45 Engine Specs

Connecting rod lower end bearing: .0007" to .001" loose.

Forked rod must have .006" to .010" play between flywheels.

Roller and retainer assembly must be narrower, but not more than .010" narrower, than forked rod.

Connecting Rod Placement

On 1939 and later engines, the forked rod is at the rear. On earlier engines, the forked rod was the front rod.

======================

Trial-fit Engine Cases

Without gasket sealer, engine cases are joined with two cap screws at the top, and two studs with nuts at the bottom.

The crank should rest centered in the cases. It should not run to one side or the other when rotated.

Flywheel end play can now be checked.

Crankshaft Clearance

Having proper flywheel end play is important. Too much play affects the stability of the piston in the cylinder. Not enough end play will cause the bearings to overheat.

Recommended end play clearance is .012" to .014". It's better to have a little more play than too little play.

Flywheel thrust washers are sold as a kit and have 10 different sizes.

If possible, try to have left and right thrust washers approximately the same thickness. Ideally, just one each on both sprocket and pinion shafts.

======================

Final-Fit Engine Cases

When you're satisfied with the fit, it's time to seal the cases.

There are several good products to seal motorcycle engine cases. For this engine, I chose Permatex Ultra Grey.

After applying to both case surfaces, the sealant was allowed 5 minutes get a little tacky before final assembly. The two bolts and four studs were then installed and tightened.

======================

Related Articles:

Harley 45 Engine Build

Harley 45 Engine Teardown and Inspection

Repair Stripped Threads In Aluminum

Harley 45 Engine Assembly

Install Harley 45 Cams

Harley 45 Cylinder Assembly

Harley 45 Scavenger Oil Pump Repair

Harley 45 Drivetrain

Harley 45 Frame Choices

=======================

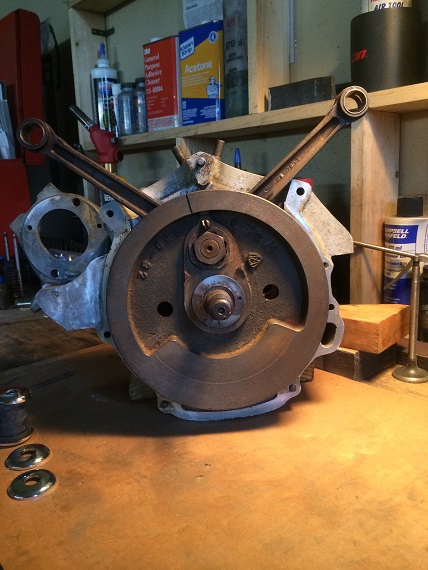

Harley 45 Engine Stand

This is a simple engine stand I welded up to make working on the motor a little easier. It also gave me something to mount the dial indicator to check for crankshaft end play.

Read: DIY Harley Engine Stand

As an alternative for a stand, you can use a couple 4x4 wood blocks.

=======================