DIY vs Machine Shop

Article by Vintage Vinny

Should you farm out your engine work to a machine shop or do it yourself?

If you have past mechanical experience, and are willing to devote the time and invest in a few tools, trusting your own abilities may be the better choice.

The Time Factor

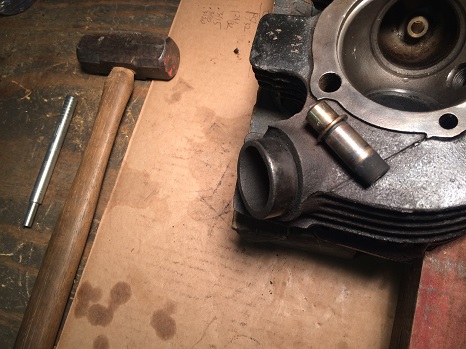

In 2024, I brought a Norton 850 cylinder to a local machine shop. Although I've bored cylinders before, this one was questionable, and the machinist had experience with Norton engines.

Before I dropped the parts off, I was told they were four weeks behind, and I was OK with that.

After not hearing anything for five weeks, I reached out to them.

"Good morning, any update on the Norton 850 cylinder?"

"Still trying to get to it. The local shops have been killing us with work."

Ok, so they're obviously taking in work after mine and finishing it before mine. I understand they're in business to make money and they've got bills to pay.

But, because of their expertise and reputation and proximity, I decided to be patient. Finally, after two months and another polite phone call, they started to work on it.

******************

Shipping A Motorcycle Engine

Some of our old bikes require specialty tools and skills, which get more scarce with every passing year. There will always be shops that work on vintage bikes, but will they be in driving distance of your home? If not, factor in another $350-$500 for shipping (there and back).

To ship engine parts to and from a shop is expensive, and won't get any cheaper. It also exposes parts to damage if not packed and shipped properly.

******************

Machine Shop Complaints

I've heard more than a few bad stories regarding the quality of machine shop work.

Machining costs always seem reasonable at first, but are likely to change. They may quote you low to get the job in the shop, then sell you other services along the way. Some of this is honest, but some of it is not.

Consider their precision tools that a machine shop uses day in and day out, are they ever checked and recalibrated? The difference of a thousandth of an inch on lower-end clearance is critical. It could mean the difference between a 50,000 mile engine or a 5,000 mile engine.

The Quality Factor

Remember that "professional" is not a skill level, it only indicates compensation.

******************

Rely On Your Own Work

Years ago, I started learning new skills and acquiring specialty tools as I have needed them. Today, I can perform just about every aspect of a motorcycle engine build.

It is a time-consuming process, but it's a good feeling to control an entire project from start to finish.

******************

Motorcycle Engine Tools

The money you save by doing it yourself gives you a bigger budget to buy tools you need, and rebuilding any motorcycle engine requires specialty tools.

Everything is easier when you have the proper tools.

Read: Motorcycle Repair Tools and Equipment

If you don't have the required tools, you can buy them new or used, but some you can make yourself. Depending on how creative you are, many can be fabricated.

Read: DIY Motorcycle Tools

******************

Notes and Misc

Here's some tips on finding a shop that will be reputable, dependable, reasonably priced, and familiar with vintage engines:

If you don't know of anyone who's used their services, read online reviews about them.

Make sure you specify everything that you need to have done, and leave no room for interpretation.

Ask them what procedures they will use to do the work. In other words, test their knowledge.

Don’t assume anything - get all service work to be performed in writing BEFORE starting.

Is rebuilding a motorcycle engine something that can be done in your home garage?

Yes, but first you should understand the how and the why. This is done by reading everything you can on the subject.

A motorcycle engine build requires measuring and re-measuring, assembly, disassembly, and reassembly. Make sure everything is right before continuing to the next step.

******************

Related Articles:

DIY Motorcycle Cylinder Boring

Motorcycle Valve Job

Motorcycle Engine Tools

Crankshaft Journal Polishing By Hand

Best Engine Assembly Lube

DIY Motorcycle Tools

Best Digital Caliper For Engine Building

Repair Stripped Threads In Aluminum