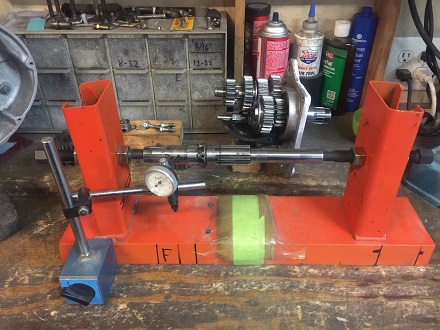

DIY Flywheel Truing Stand

Article by Mark Trotta

Buying a pre-made flywheel truing stand is a nice luxury, but homemade units can work just as well.

This stand works with Harley Flathead, Panhead, Shovelhead, and Ironhead flywheel assemblies. Perhaps some others as well.

Having two dial test indicators (one on each side) makes measuring easier. You can get by with just one, but you'll be moving it from side to side to get left and right readings.

A magnetic base dial indicator allows many options as to where it can be mounted.

It's best to clamp dial test indicators as close as possible to the flywheel shaft. For best results, position so that the stem is parallel to the direction of component motion.

The alignment of the two center bolts is not super-critical. They just provide the two points that the flywheels and shafts ride between.

A length of 4" steel C-channel stock was used for the base. The metal was cut with a Milwaukee Portaband.

***********************

Truing vs Balancing

Truing is about how the two flywheels mate to each other. Balancing is about the actual weight of the flywheels, spoken in terms of grams.

On Harley-Davidson V-Twins, truing is done at the factory. Balancing is done as well, but not to the same degree of precision as would be required on a high-revving race engine.

On street-driven bikes, truing is mandatory, balancing is optional.

***********************

Other Uses

This stand can be reconfigured to check run-out on transmission sprocket shafts and pinion shafts.

The picture below shows checking mainshaft straightness.

This mainshaft measured an acceptable run-out of .001". Anything past .003" is questionable.

***********************

Related Articles:

Motorcycle Engine Tools

Best Engine Assembly Lube

Best Digital Caliper For Engine Building

DIY Motorcycle Tools

Milwaukee Portaband Review