Crankshaft Journal Polishing By Hand

Article by Vintage Vinny

Benefits to polishing crankshaft journals include friction reduction, temperature reduction, and getting maximum bearing life. Doing it yourself will take a lot longer than having it done at a machine shop, but no special tools or equipment are needed.

Measure For Roundness

To begin with, journals need to be perfectly round. This must be measured with a micrometer--a vernier or dial digital caliper is not an accurate way to check for roundness. Plastigage is also inaccurate here.

NOTE: A quality micrometer that measures down to 0.0001 inch is a must. Cheaper tools often only measure down to 0.001 inch.

Shown: Mitutoyo 1-2" Outside Micrometer

To establish roundness, take measurements from at least two different angles (example; 90 degree and 180 degree). If ovality exceeds .0015", it'll have to be machined.

Nicks and Scratches

A small nick can sometimes be taken out, but if a journal is grooved or deeply scratched, polishing won't remove it.

******************

Machine Shop vs DIY

The 'professional' way of polishing a crank is by spinning the crank and using a polishing belt. It's an inexpensive service, so if your engine's already at a shop, it's best to have them do it. If not, does anyone in your area offer this service? I'm not a big fan of sending out vintage engine parts in the mail.

And what about the turn-around time?

Read: DIY vs Machine Shop

******************

Getting Started

Other than a sturdy workbench and vice, polishing crankshaft journals requires patience and attention to detail. Materials needed include assorted grits of Emory cloth or wet/dry sandpaper, a shoelace, and a pair of scissors.

Emory Cloth vs Sandpaper

Factory service manuals recommend Emery cloth, which can be used wet or dry. Personally, I prefer wet/dry sandpaper (400, 600, 800, 1000), which probably takes longer. Either will get the desired results.

Prop Up Work Piece

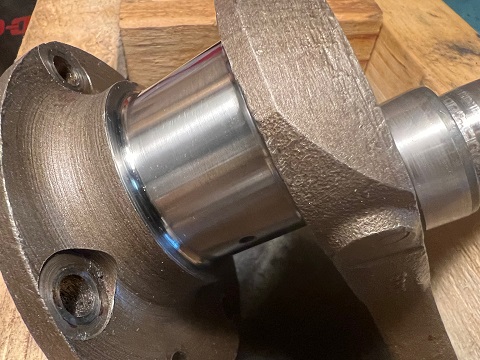

On this two-piece Norton 850 crankshaft, I secured it in soft jaw pads in my workbench vise.

******************

Lubricant

For lubricant, honing oil is good if you have it. I use WD40 in a spray can.

Cut the sandpaper into strips just wide enough to fit the journal, and enough to wrap it and have overlap.

Example: On this 1.75" crank journal, I'm using 8" lengths of paper about 1.7" wide.

Some like to start right off with 400 wet, but I begin with 600. If I see the 600 isn't getting it done, then I'll switch to 400. This is to avoid making any unnecessary scratches.

Spray the journal with lubricant, then wrap the paper around. Next, take a 2 or 3 foot long shoelace and make two loops around the journal and paper.

While holding the paper taut with one hand, wrap the shoelace around with your other hand.

Leave the ends of the rope equal and then pull on the ends of the rope with alternating strokes (a back and forth 'sawing' motion).

In this picture I'm using 400 grit with WD40.

The paper should be snug on the journal, but not too tight, as you don't want any of the debris you just sanded off to embed back into the journal. This is why plenty of lubricant should be used. It helps wash away the debris.

Using a gentle back and forth sawing motion, I'll do about 10-20 pulls, then stop and check progress. Remove the shoestring and sandpaper and wipe off journal with a rag or shop towel.

The dirt on the towel tells me I'm making progress.

Here I switched to 600.

A light touch is key. Changing the paper strips often also helps.

After using 800 grit, I brought the piece outside to inspect it in direct sunlight.

Results after 1000 grit paper.

You can go a step further and apply metal polish.

The term 'micro-polishing' is typically used when using a polishing compound, although many people call sanding with 1000 grit and finer micro-polishing.

******************

Notes and Misc

Remember to wash everything thoroughly when you are finished. Brake parts cleaner and shop towels work well.

If you're going to chamfer the oil holes, do so before starting the polishing process.

On this Norton Commando crankshaft, the drive-side race was also polished (400 wet).

******************

Related Articles: