Anaerobic Gasket Sealer Review

Ease of use, easy to clean up, no harm to oil circuits, and an indefinite shelf-life. That's why you want anaerobic gasket sealer between your motorcycle's engine cases.

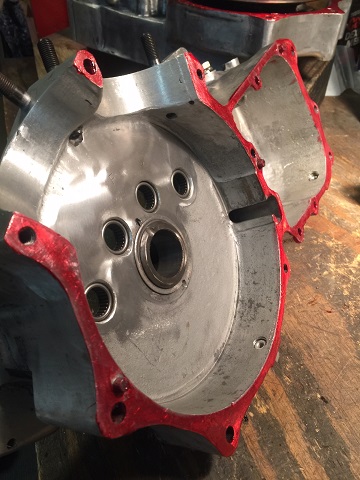

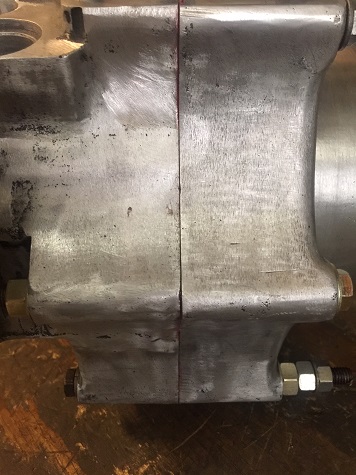

Above and below, author's 1962 Sportster engine build

***********************

Why You Shouldn't Use Silicone Sealants

Starting in the seventies, silicone sealants began replacing conventional gaskets in many automotive applications. Today, silicone-based gasket makers are very popular with professionals and DIYers. But on a motorcycle engine, no matter how careful you apply them, there is always a risk of unwanted globs ending up in the oil circuit.

There is also another concern with silicone on motorcycle engines. Any fuel dilution in the oil will eat away at silicone sealant. For example, if gas leaks through the carb while your bike is on it's side-stand, the unburned gas gets into the oil, and dissolves silicone sealant.

***********************

What Is Anaerobic Gasket Sealer?

The definition of anaerobic is "existing in the absence of oxygen".

What this means is, anaerobic gasket sealer only cures when you take the air away from it (like when it's between engine cases). If you apply a little extra, it doesn't harden and clog oil passages in the engine.

Since it only hardens in the absence of oxygen, you have more time assembling and tightening down the case bolts. This is a welcome relief for me, because I like to work slowly and methodically. There is no pressure to get parts bolted up quickly.

***********************

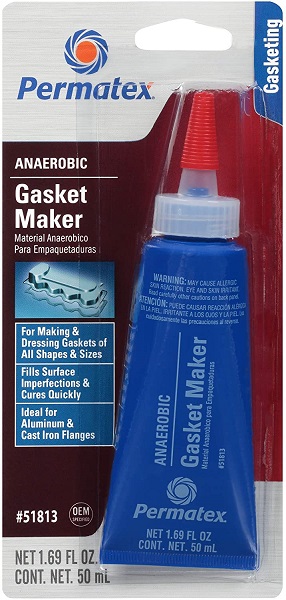

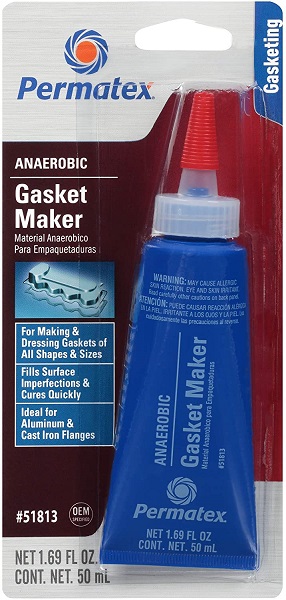

Permatex 51813 Gasket Maker

After years of using conventional gasket sealants, I switched over to Permatex #51813 Anaerobic Gasket Maker. I've used it on my last three engine builds without any leaks or seepage. And on 50 and 60 year-old Harleys, that's saying a lot!

Permatex states their anaerobic gasket maker is non-corrosive, and designed for use on aluminum, iron, and steel flanged mating surfaces. When a conventional gasket is unavailable, it will fill small imperfections in mating surfaces up to .015".

Anaerobic sealant works very well with aluminum engine and transmission cases. It also works well on outboard motor crankcase halves.

It's also good for sealing bolt threads where oil is present.

***********************

Surface Prep

Before applying, engine case surfaces need to be clean and dry. To be honest, some builders don't take surface prep seriously enough, and then blame the sealant for not doing it's job.

Take the time to get the mating surfaces completely clean and oil free.

The engine cases also need to be flat. This is of particular importance after an aluminum case was repaired by welding, which often distorts and warps the metal.

After surface prep, wipe on sealant with a gloved finger.

After the cases are joined and tightened, there will be a small amount of "extra" sealant that squeezes out of the surface faces. This is normal and Ok.

Excess sealant can be wiped off with shop towels.

Anaerobic gasket maker cures to a solvent-resistant seal and does not tear or decay during service.

If possible, allow to dry for 24 to 36 hrs for full cure before adding fluids.

The glob in the picture was all that was needed to seal a pair of Ironhead Sportster engine cases.

***********************

Indefinite Shelf Life

Because it doesn't harden until oxygen is removed, any unused portion will last an indefinite amount of time. It doesn't harden in the tube, so it stays usable for a long time.

Another advantage is that parts disassembly is easy. Even after extended service, old gasket material is removed easily with a razor blade or gasket scraper.

This came in handy when I had to disassemble a pair of 1965 Sportster cases after one of the case bolts stripped.

***********************

Does Anaerobic Gasket Sealer Have An Odor?

There is a very light smell, but nothing nasty.

***********************

Is An Activator Needed For Anaerobic Sealer?

The package instructions mention using an activator spray, or surface prep spray, which confuses some people. Permatex states that activator spray is only needed when you are sealing porous surfaces.

***********************

Conclusion

I haven't given up on silicone gasket sealants. I still use them on automotive valve covers and water pumps and some other things, but nowhere oil related. No matter how carefully you apply it, there is always a risk of unwanted globs getting into the oil circuit.

And why take that risk if you don't have to?

Shop: Permatex Anaerobic Gasket Maker

***********************

It's also available in a caulking tube size, which dispenses easily.

Shop: Anaerobic Sealant, 300 ml Cartridge

***********************

Related Articles: