7 Drill Press Uses For Motorcycle Repair

Article by Mark Trotta

Every year, I keep finding new uses for my old drill press.

In no particular order, here are seven ways a drill press can help you repair old motorcycles:

******************

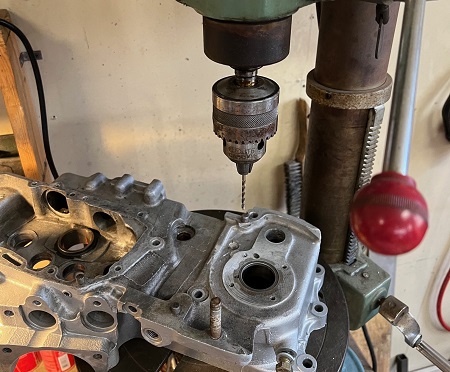

Drill Out Broken Bolts

While overhauling Norton Commando forks, one of the fender retaining studs snapped off in the left slider.

After center-punching what was left of the stud (while clamped in a workbench vice), the slider was fitted into a drill press vice.

First, a small pilot hole was drilled. Next, two progressively bigger holes were drilled.

The remains of the stud were then removed with a spiral screw extractor.

******************

Remove Carbon From Valves

Here's an easy way to clean carbon off engine valves. Install and tighten the valve into the chuck like you would a drill bit.

Turn machine on (low speed) and clean valve with steel wool.

******************

Cam Bushing Pin Installation

While replacing Sportster cam bushings, new holes are needed for the new bushing pins, as they will not fit tightly back into the old holes. With the help of a small jig, this can be done in a drill press.

The tool in the picture below is made by Jim's Tool.

Notice the green tape on the drill bit. That's my "stop collar" so I don't go any deeper than necessary. Most drill presses have a locking hub for this, but I find that a piece of tape is quicker.

******************

Drill Out Security Bolts

How do you remove a security-head bolt without the proper tool?

Answer: With a drill press!

Replacing the ignition switch on a BMW R1100R was necessary due to a stuck key. After removing the upper fork bracket, two security bolts were drilled out and replaced with Allen head bolts.

First, a center punch, then each bolt head was drilled with successive-sized drill bits.

Old bolts were then able to be removed with a spiral screw extractor.

The old key cylinder was held in place by two rivets, which were also drilled out while mounted in a drill press vice.

******************

Fabricate Custom Brackets

The horn on this custom 1974 Harley was relocated from it's original location to the front frame tubes.

After a piece of metal stock was cut to size, holes were marked off and drilled.

Corners were rounded and sanded smooth, then given a few coats of black paint.

Carburetor Bracket

Harley V-Twins vibrate quite a bit while running, which may lead to cracked intake seals, vacuum leaks, and rough running. Adding a carburetor support bracket is a smart idea.

You can buy a carb bracket, but they're fairly easy to make if you have a good solid bench vice and a drill press.

The one in the pictures above was made from a metal shelf bracket.

******************

Drill Into Pipes and Tubes

Ever try to drill a hole through a round pipe or tube with a hand-held drill? A drill press and a drill press vice makes this easy.

Fit the part into a drill press vice. Use a center punch to start the hole.

Note the wooden T-handle on this DIY damper rod extraction tool.

******************

Drill Straight Holes In Metal

Hand-held drills run too fast and take too long to accurately drill through metal.

A drill press provides much better control and precision.

******************

Repairing stripped threads in aluminum, such as on this 1962 Sportster engine case, require enlarging the damaged thread to add Helicoil inserts.

Thread Tapping

Starting a new thread tap doesn't have to be hard. Hand tapping and hand die work can be done on a drill press. The motor doesn't get turned on, the drill chuck is used to align the tap or die.

With the drill press machine turned off, and the work-piece flat on the tray, I am manually turning the chuck with my hand to tap a thread.

Remember to go in slow, and come out slower.

******************

Accessories

Since a primary consideration of any setup is to have the workpiece properly anchored, a 'must-have' accessory is a drill press vice.

For larger work, the workpiece can be secured directly to the table. T-slots in the table make this possible.

Another 'must-have' is an assortment of hold-down clamps.

There's many styles of hold-down clamps. I keep an assortment of C-Clamps in several sizes.

Buffing and Sanding

To clean small and fragile parts, a drill press spins much slower than a bench grinder, so you get better results (plus it's safer).

A wire wheel or sanding drum can be mounted into the chuck for buffing/sanding. Sometimes, you can mount the part into the chuck, such as this brake caliper piston.

Other Drill Press Functions

A boring tool can be inserted into the chuck, and any size hole that which the tool holder will fit can be bored.

To get even more out of your drill press, there are counter-sink, counter-bore, and reamer attachments. If a part requires clearance for a flat-head screw, you can countersink the hole after drilling it. Or, if you are using cap screws, you can counter-bore the hole.

******************

Floor Mount vs Bench Mount

There are two basic styles of drill presses; freestanding (floor-mounted) and benchtop (workbench mounted). In my small garage workshop, floor space is too precious for a floor drill press.

My drill press is a 45 year-old bench-top model. The base is 10.5" by 8".

It stands 40 inches tall and is very heavy!

******************

How To Change Drill Speed

Drilling metal requires much lower speeds than wood does.

To change drill speed, open the cover on top of the press, and you will see two sets of pulleys and a belt. To get the lowest running speed for drilling metal (150 rpm on this machine), put the belt on the biggest pulley up front and smallest on the back.

******************

Safety Precautions

Drilling machines are one of the more dangerous hand-operated pieces of shop equipment.

Always wear eye protection while operating.

Never make any adjustments while the machine is operating.

Never clean away chips with your hand. Use a brush.

******************

Related Articles: